This article will help you understand!! (Picture and text explanation)

What is stainless steel?

It is what we commonly call "white iron" in Taiwan, and the so-called "stainless" means that it is less likely to rust than ordinary steel, but it does not mean that it will not rust!!!Stainless steel is made of different metals (Carbon, Iron, Chromium, Nickel, Manganese, Molybdenum, etc.) composed of alloy steel with different contents.

The Chromium content must be at least 10.5% to be called true stainless steel. Stainless steel made with different metal proportions is classified with different numbers. Due to different purposes of use, the raw material composition of each series will be different.

Stainless steel is not easy to rust because...

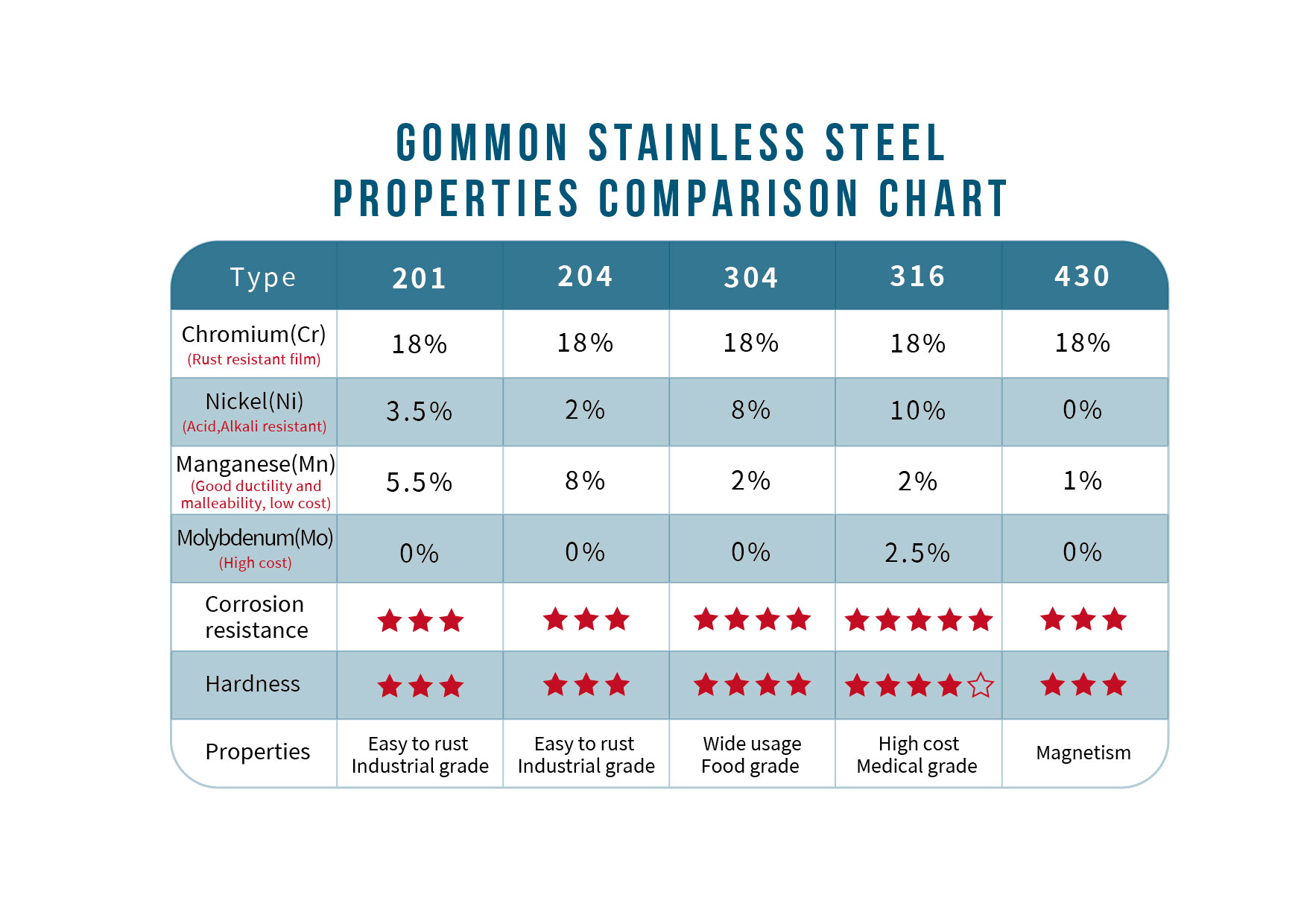

Because Chromium (Cr) will form a transparent and dense protective film of Chromium Oxide on the steel surface, which can prevent oxygen from coming into contact with iron. Nickel (Ni) can promote the regeneration of the protective layer. However, the 18-8 or 18-10 seen on general product labels actually refers to the content ratio of Chromium (Cr) to Nickel (Ni). If stainless steel contains Molybdenum (Mo), it can effectively stabilize the film in the presence of chloride and quickly repair the surface with corrosion resistance. Therefore, the most important thing when choosing stainless steel is to understand the proportion of stainless steel, not that the bigger the number, the better.In the early days, the materials used in stainless steel food containers in Taiwan were mostly 300 and 400 series stainless steels. The most common ones are 304, 316, 403, 410 and 430. In recent years, 200 series stainless steels have been developed that use Manganese instead of Nickel, such as 202 and 205 steel.

Scroll left to find more information

| Element | Functional characteristics |

| Chromium(Cr) | Anti-oxidation, a layer of Chromium Oxide protective film will be formed on the surface to prevent rust |

| Nickel(Ni) | Acid and Alkali resistant material |

| Manganese(Mn) | Can reduce costs |

| Molybdenum(Mo) | Higher hardness and strength, more corrosion resistance, higher price |

What are the differences between commercially available stainless steel materials labeled 200, 300, and 400 series?

All three series of steels contain Manganese, with the 200 series having a higher Manganese content and the 400 series having the lowest nickel content. Therefore, the rust resistance of each series of steel materials is different.Industrial stainless steel is mostly 200 series, 304 and 430 stainless steel are food grade, and 316 stainless steel is medical grade. Among them, the content of Nickel (high cost) is the main reason for the difference in corrosion resistance and price.

Developed during World War II due to insufficient supply of Nickel metal. The Nickel content was halved and replaced with cheaper Manganese as a replacement for 300 series steel. It has basic hardness and corrosion resistance, relatively cheap, but is relatively easy to corrode. It belongs to industrial grade stainless steel and is suitable for iron windows, iron doors, beams and columns, etc.

300 series stainless steel: food grade

High content of Chromium and Nickel, achieving the best balance in hardness, corrosion resistance and processing, strong and durable, it is the first choice for tableware and the most widely used.

304 stainless steel is food-grade stainless steel. It may have weak magnetism due to processing, but not strong magnetism. Suitable for tableware, corrosion-resistant containers, furniture, railings, medical equipment, etc.

316 stainless steel contains Molybdenum (Mo), so it is more corrosion-resistant, stronger, and more expensive. It is completely non-magnetic and belongs to medical grade stainless steel. Suitable for surgical equipment, fertilizer production equipment, food industry, coastal facilities, high-priced pots, etc.

400 series stainless steel: Food grade

A pure Iron-chromium alloy, Nickel-free or low-nickel stainless steel. It is easier to rust than the 300 series and has a lower price. However, the advantage is that it is easy to process and has better nitric acid corrosion resistance. It is magnetic. Therefore, it can be used to distinguish between 304 and 316 stainless steel.

Because 430 stainless steel has good nitric acid corrosion resistance, it is most widely used in automotive trims and related components. It is also commonly used in the inner layers of kitchen utensils, dishwashers, and washing machines.

After having a basic understanding of stainless steel, more detailed explanations

What is the difference between 204 and 304 stainless steel??

Due to different composition ratios, 204 stainless steel is easier to rust than 304 stainless steel. Therefore, 204 stainless steel is cheaper. Therefore, 204 stainless steel is often used as a substitute for 304 stainless steel. For use in general environment and cost reduction is the main factor, 204 stainless steel will be the better choice. However, if corrosion resistance is required during use, it is recommended to choose 304.Consumers often have doubts about food safety issues and tableware selection.

We have compiled some information about Manganese.

What is the impact of manganese on the human body?

Manganese is actually a trace mineral necessary for human metabolism. Manganese and its compounds are widely found in nature, including soil, rocks, air, water, and animals and plants. Only about 3 to 5% are inhaled or absorbed through the digestive tract. Foods rich in manganese include grains, nuts and seeds, beans and fruits. Medicines such as antacids and laxatives also contain Manganese. Manganese deficiency can cause symptoms such as osteoporosis and growth retardation, and excess may cause neurological-related diseases.Do I need to worry about manganese dissolution when using 200 series stainless steel food containers?

Although there are many doubts on the Internet about the precipitation of Manganese from 200 series stainless steel, according to the announcement of the Food and Drug Administration: 101 The dissolution test results of Manganese from stainless steel of different materials, if 4% acetic acid is used as the solvent (placed at60°C, 30 minutes), the maximum Manganese dissolution amount of 200 series steel is 4.39 ppm (mg/kg).

For example: drink a bowl of about 200g soup (packed in a 200 series stainless steel container), and only consume 0.88 mg of Manganese, which is much lower than Daily consumption of a bowl of brown rice (calculated based on 80g of brown rice) contains Manganese (3.77 mg).

Therefore, under normal use, 200 series stainless steel will not dissolve excessive heavy metals due to hot and cold temperatures or pH value. You don’t need to worry too much.

However, due to its poor anti-rust properties, it is rarely used as tableware. It is recommended to pay more attention before purchasing tableware.

Addition: Each model of stainless steel is provided below to check its main

Scroll left to find more information

| 200 series | |

| Model 201 | Lower cost, the nickel content is very low, the anti-rust property is poor, and it contains high Manganese content to increase ductility and malleability. Often used in industries, such as iron windows, iron doors, beams and columns, railway vehicles, etc. |

| Model 202 | It has basic acid and alkali resistance. Because of its low price, it is often used as a substitute for 304 stainless steel. It easily precipitates Manganese after heating and is not suitable for use as tableware. |

| 300 series | |

| Model 301 | Has good ductility and malleability, mainly used in finished products. It can also be hardened by mechanical processing. Good weldability. Wear resistance and fatigue strength are better than 304 stainless steel, products such as: springs, steel structures, wheel covers. |

| Model 302 | The corrosion resistance is the same as 304, but the strength is better due to the relatively higher carbon content. |

| Model 302B | It is a stainless steel with a high silicon content and has high resistance to high temperature oxidation. |

| Model 303 | By adding a small amount of sulfur and phosphorus, it is easier to cut than 304. |

| Model 304 | Universal model; mainly available in 18 (chromium)/8 (nickel) and 18/10 stainless steel. Products such as: corrosion-resistant containers, tableware, furniture, railings, and medical equipment. The standard composition is 18% chromium plus 8% nickel. It is non-magnetic. When the impurity content is high, it may occasionally show weak magnetism after processing. |

| Model 304L | Same characteristics as 304, but has low carbon content, so it is more corrosion-resistant and easy to heat treat. However, it has poor mechanical properties and is suitable for welding and products that are not easy to heat treat. |

| Model 304N | Same characteristics as 304. A nitrogen-containing stainless steel. Nitrogen is added to improve the strength of the steel. |

| Model 305 / 384 | Containing high Nickel content, hardening rate is low, and it is suitable for applications that require high cold formability. |

| Model 309 | Better temperature resistance than 304. |

| Model 309S | Contain large amounts of Chromium and Nickel, so it has good heat and oxidation resistance. Products such as: heat exchangers, boiler components, and jet engines. |

| Model 310S | The content of Chromium and Nickel is high, so it has the best heat and oxidation resistance. Products such as: heat exchangers, boiler components, and electrical equipment. |

| Model 316 | The second most widely used steel type, mainly used in the food industry and surgical equipment, has a special structure that resists corrosion due to the addition of Molybdenum. Because it has better resistance to chloride corrosion than 304, it is also used as "marine steel". SS316 is usually used in nuclear fuel recovery devices. 18/10 stainless steel is also generally qualified for this application grade. Used in chemical, seaside and other corrosive environments, ship assembly, and building materials. |

| Model 316L | Because of its low carbon content, it is more corrosion-resistant and easier to heat treat. Products such as: chemical processing equipment, nuclear power generators, and refrigerant storage tanks. |

| Model 321 | The addition of Titanium reduces the risk of material weld corrosion, other properties are similar to 304 and is suitable for welding brewing equipment, steam pipes, and aviation parts. |

| Model 347 | Adding the stabilizing element niobium, it is suitable for welding aircraft parts and chemical equipment. |

| 400 series | |

| Model 408 | Good heat resistance, weak corrosion resistance. |

| Model 409 | The cheapest model, suitable for welding, often used as automobile exhaust pipes and petroleum equipment. |

| Model 410 | It has good wear resistance but poor corrosion resistance, so it is suitable for pumps. The raw materials are cheap, magnetic, and can be hardened by heat treatment. General uses include bearings, medical equipment and knives, etc. |

| Model 416 | Sulfur is added, thereby improving the material's processability. |

| Model 420 | Containing higher carbon, higher hardness and strength, the original stainless steel. Can be made very bright, suitable for knives, springs, surgical instruments, razor heads, and valves. |

| Model 430 | It has low carbon content and good formability but has poor temperature and corrosion resistance and is magnetic. Suitable for fasteners, tableware, and furniture items. |

| Model 434 | Contains Molybdenum, so corrosion resistance is better than 430, suitable for tableware, wipers, and automobile decoration. |

| Model 440 | High strength cutting tool steel, higher carbon content and a hardness of up to 58HRC, which is the hardest stainless steel. The most common application example is "razor blades". |

| 500 series: Heat-resistant Chromium alloy steel. | |

| 600 series | |

| Model 630 | The most commonly used precipitation hardened stainless steel model, also commonly called 17-4. |

References: Wikipedia/Food and Drug Administration of the Ministry of Health and Welfare-Stainless steel food containers_Q&A/ Food and Drug Administration says 200 series stainless steel is OK, doctors recommend 304